Comprehensive specifications and performance data for drainage professionals

High-performance modular drainage systems engineered from 100% recycled materials

Vertical hydraulic conductivity

vs concrete systems

Design life expectancy

Material composition

Two-component system: Trough units (A or B) sit on the drainage ditch floor to channel water, while Stacker units placed on top filter water down into the trough below. Water then flows through the trough to connected catch pits.

| Flow Rate | 679.5 L/min per metre |

| Load Capacity | 506,000+ cycles tested |

| Storage Capacity | 45% void space |

Ultra-lightweight surface drainage solution for rapid deployment. Perfect for verges, embankments, sports fields, and distributed drainage applications.

| Permeability | 49 L/m²/s |

| Weight | 44 kg/m² (50mm) |

| Compressive Strength | 250 kPa |

Comprehensive technical data for the complete Rosehill Drainage System

| Component | Length Options | Weight |

|---|---|---|

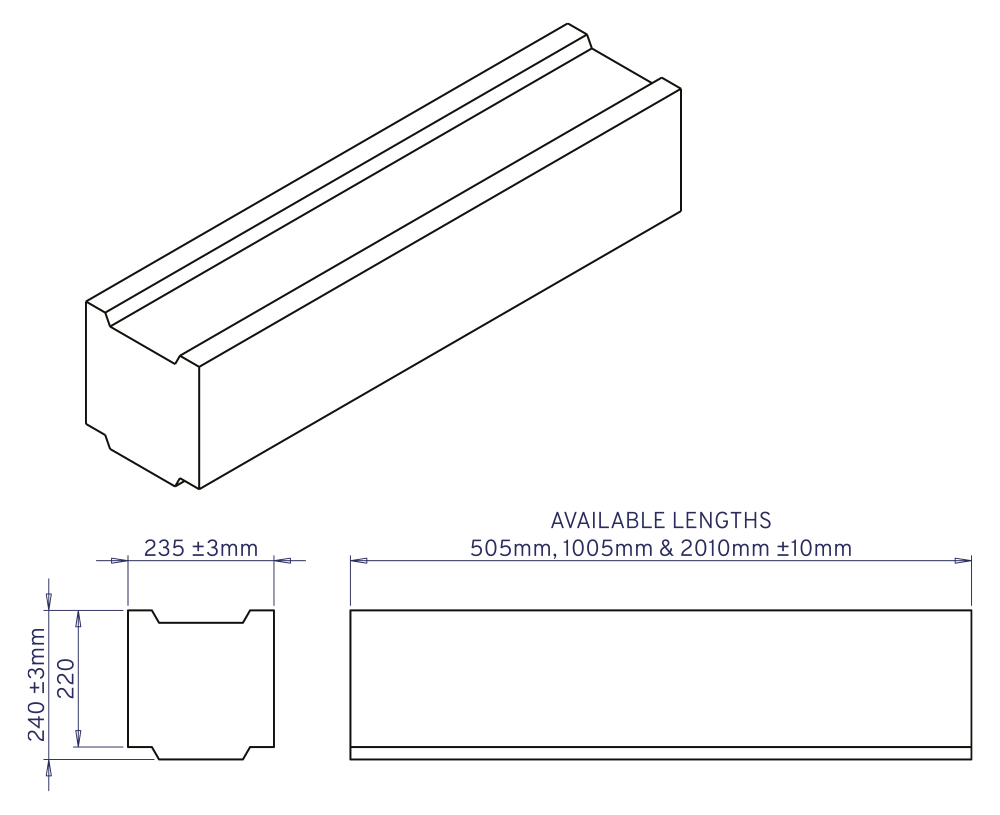

| Stacker Units | 500mm, 1000mm, 2000mm ±10mm | 16.8kg, 33.6kg, 67.2kg |

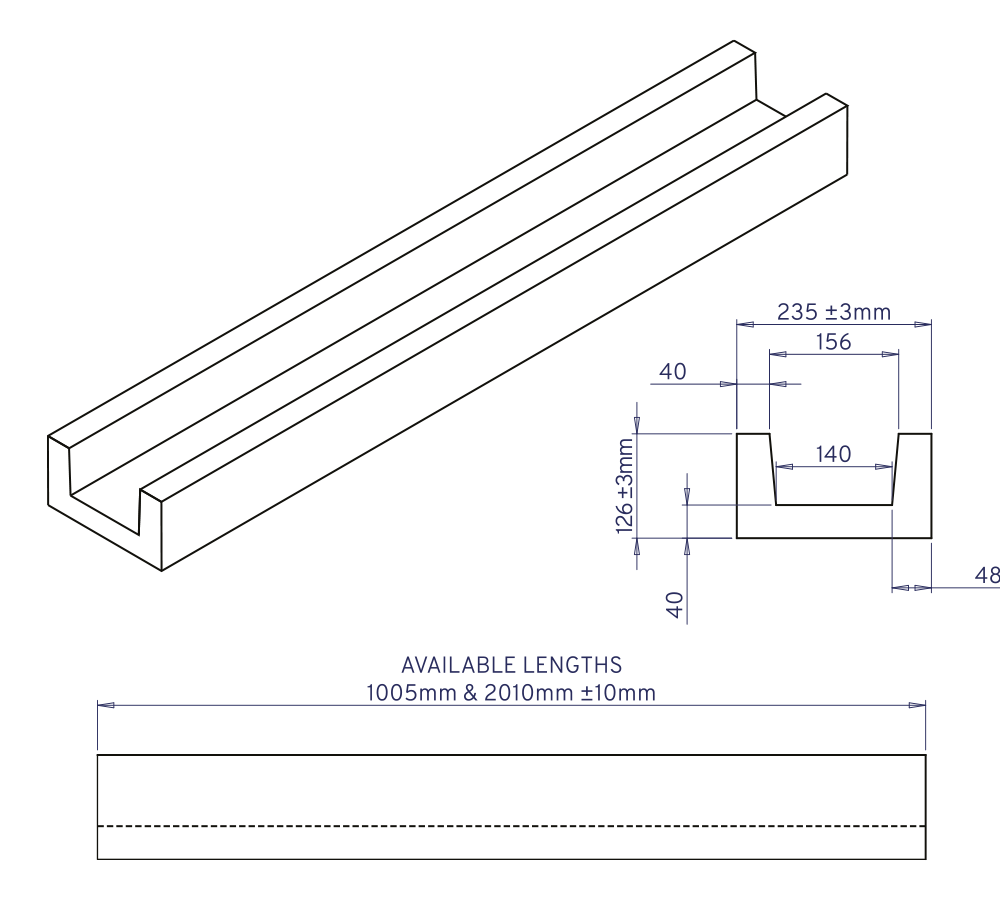

| Trough A (Standard) | 1000mm, 2000mm ±10mm | 18.9kg, 37.8kg |

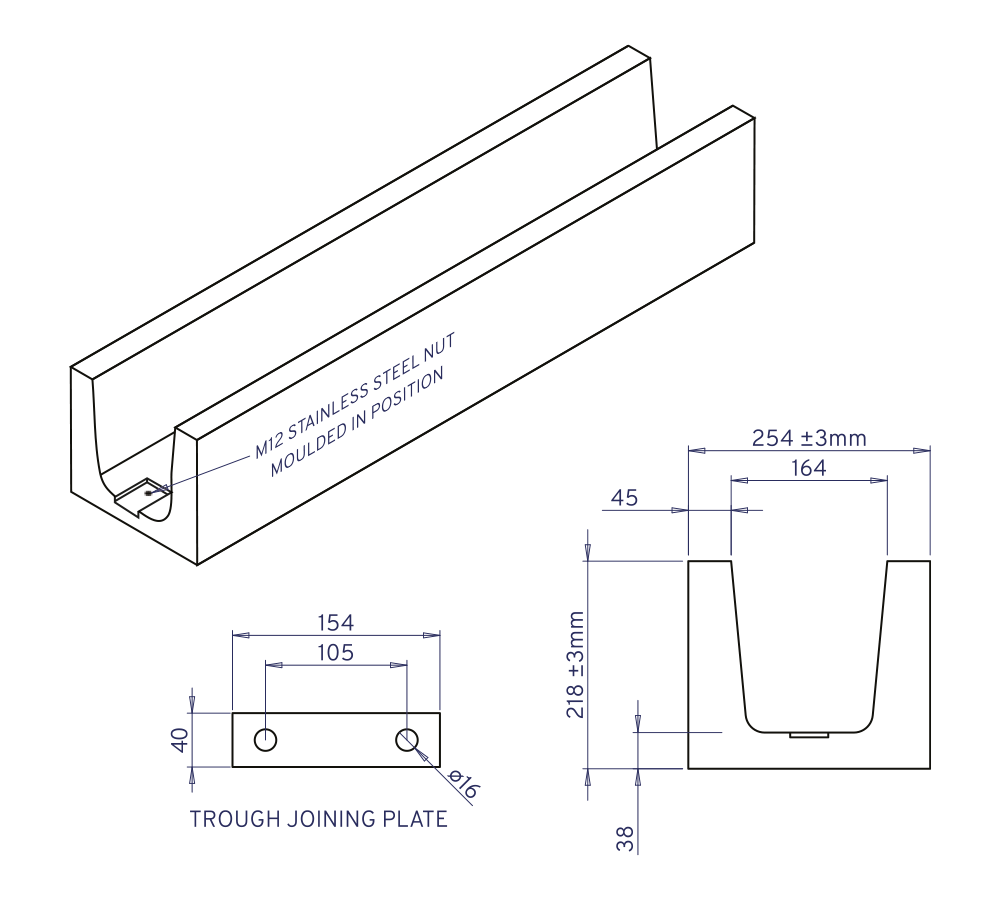

| Trough B (Large) | 1000mm, 2000mm ±10mm | 33kg, 66kg |

| Material Composition | 90% Recycled Content | Zero Virgin Rubber | |

| Operating Temperature | -40°C to +80°C | |

| Density | 750 kg/m³ | |

| Property | Value | Standard |

|---|---|---|

| Water Permeability | 49 l/m²/s | BS EN 12566 |

| Vertical Hydraulic Conductivity | 176.4 m/hr | ASTM D2434 |

| Flow Rate Large Trough | 42.6 l/s @1 in 100 | InfoDrainage modelling |

| Horizontal Flow (1:10 slope) | 0.52 l/s/m | EN 12566-1 |

| Horizontal Flow (1:100 slope) | 0.063 l/s/m | EN 12566-1 |

| Avg. Void Ratio | 30-45% | ASTM C642 |

| Property | Value | Standard |

|---|---|---|

| Compressive Strength | 2.5 MPa | BS EN 12390-3 |

| Fatigue Resistance | 506,000+ cycles | BS EN 1991-2 |

| Creep Deformation | <2% over 50 years | Long-term testing |

| Freeze-Thaw Resistance | 100+ cycles | BS EN 12390-9 |

| Chemical Resistance | Oils, salts, acids | BS EN 13529 |

| UV Stability | 50+ years | Accelerated testing |

| Certification | Status | Application |

|---|---|---|

| ISO 9001:2015 | Certified | Quality Management |

| Network Rail HA104/09 | Approved | Trackside Drainage |

| National Highways | Compliant | DMRB CD 529 & CD 530 |

| UKAS Testing | Accredited | Hydraulic Performance |

| CE Marking | Compliant | European Standards |

| Environmental | 90% Recycled | Sustainability |

Comprehensive specifications for surface drainage applications

| Category | Property | Value | Standard |

|---|---|---|---|

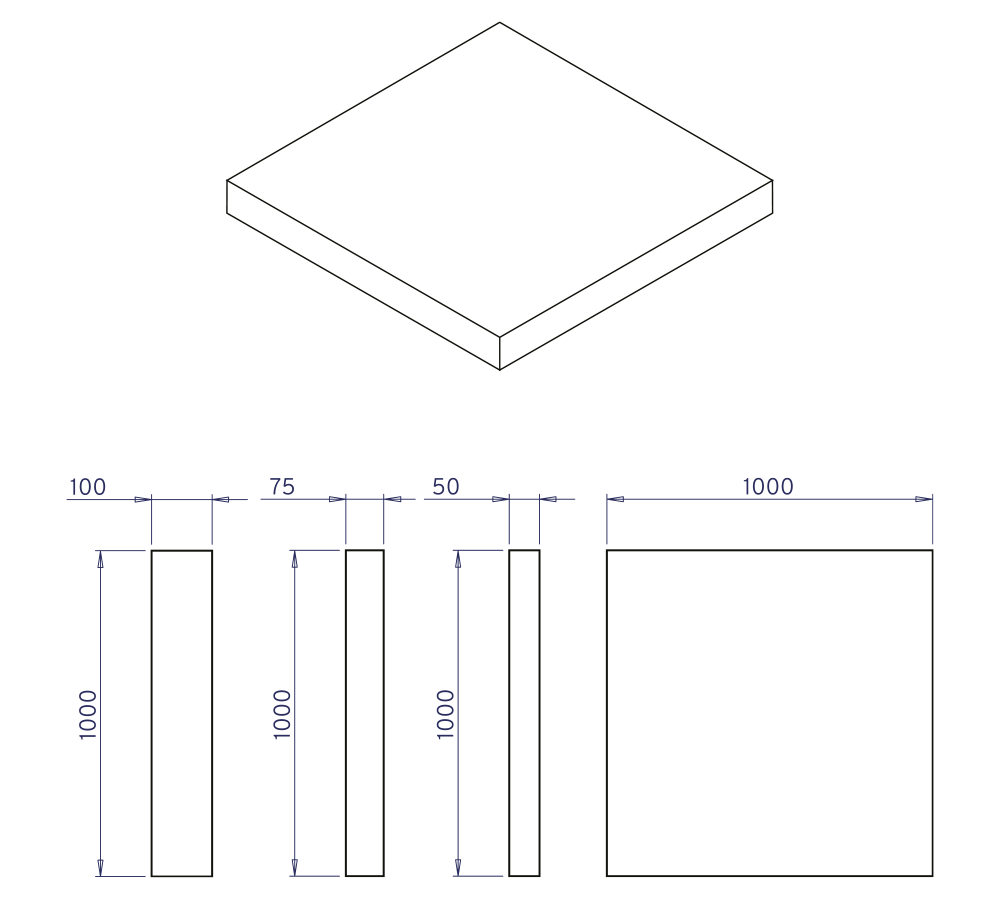

| Physical Properties | Standard Sheet Size | 1m × 1m | - |

| Thickness Options | 50, 75, 100 mm | ±2mm tolerance | |

| Weight Range | 44-88 kg/m² | By thickness | |

| Density | 750 kg/m³ | ASTM D792 | |

| Material Composition | 90% Recycled Rubber | - | |

| Hydraulic Performance | Vertical Permeability | 49 L/m²/s | UKAS Accredited |

| Horizontal Flow Rate | 15 L/m/s | Laboratory Testing | |

| Water Retention | Minimal (<5%) | Drainage Testing | |

| Filtration Efficiency | Removes particles >1mm | - | |

| Clogging Resistance | Self-cleaning structure | Long-term testing | |

| Mechanical Properties | Compressive Strength | 250 kPa | BS EN 826 |

| Tensile Strength | 150 kPa | BS EN 1607 | |

| Deformation under Load | <10% at 50 kPa | BS EN 1606 | |

| Freeze-Thaw Resistance | 100+ cycles | BS EN 12390-9 | |

| UV Stability | 50+ years | ASTM G154 | |

| Service Temperature | -40°C to +80°C | All conditions |

Technical drawings and configuration details

Standard trough unit dimensions and connection details. Base component for linear drainage systems.

Extended trough configuration for increased capacity applications. Enhanced storage volume.

Stacker unit interlocking mechanism and vertical assembly configuration for unlimited depth.

Standard mat dimensions, thickness options, and installation overlap requirements.

Comprehensive testing and regulatory compliance

All hydraulic performance data validated through UKAS accredited laboratory testing to ensure accuracy and reliability.

Accepted under HA104/09 standard for trackside drainage applications on the UK rail network.

Meets DMRB standards CD 529 and CD 530 for highway drainage systems and strategic road networks.

Extensive freeze-thaw, UV exposure, and chemical resistance testing validates long-term performance.

Fatigue testing to 506,000+ cycles demonstrates exceptional durability under repeated loading.

Manufacturing quality management system certification ensures consistent product quality and performance.

| Standard | Application | Parameter Tested |

|---|---|---|

| BS EN 12390-3 | Compressive Strength | Material strength under compression |

| BS EN 12390-9 | Freeze-Thaw Resistance | Durability under thermal cycling |

| BS EN 1991-2 | Traffic Loading | Fatigue resistance under repeated loads |

| BS EN 13529 | Chemical Resistance | Performance in aggressive environments |

| BS EN 826 | Compression Test | Deformation characteristics |

| ASTM G154 | UV Stability | Long-term UV exposure effects |

| DMRB CD 529 | Highway Drainage | Design requirements for road drainage |

| HA104/09 | Railway Drainage | Requirements for trackside drainage |